Address

Unit 7 & 24

Darton Business Park

Darton Business Park

Barnsley

Yorkshire

S75 5QX

England UK

Opening Hours

Today

08:00-17:00 08:30-17:00

View All Hours

Sunday

Closed

Monday

08:00-17:00

08:30-17:00

Tuesday

08:00-17:00

Wednesday

08:00-17:00

Thursday

08:00-17:00

Friday

08:00-17:00

Saturday

Closed

Other Dates

IN EMERGENCY CASES OUR OFFICE LINES OPERATES AN OUT OF HOUR SERVICE

About PSR Industrial Flooring Ltd

PSR Industrial Flooring have over 25 years' experience in understanding floor coatings, industrial flooring upgrades, industrial floor preparation, industrial floor grinding, industrial floor coatings, industrial floor painting, industrial floor screeds, industrial floor joint repairs, industrial floor joint re-sealing, car park decking systems and industrial resin flooring.

Operating worldwide, PSR Industrial Flooring’s practical experience and industrial flooring technical expertise enables us to give you sound advice about your flooring requirements along with a cost-effective, efficient and professional industrial flooring service.

Warehouse Flooring

PSR Industrial Flooring specialises in providing a comprehensive warehouse flooring service, helping to ensure that your floor is of the highest quality and able to easily cope with the constant demands that are present in your warehouse. We pride ourselves on our reliability, outstanding customer service and our quality workmanship and products, so no matter what the requirements of your warehouse may be, PSR Industrial Flooring can provide you with Industrial Floor Expansion Joints to create a durable surface that continues to perform well into the future.

Industrial Floor Grinding

PSR Industrial Flooring provides Industrial Floor Grinding services for a variety of different industrial and commercial environments, working to level out problem floors and offer a more even surface. Concrete Floor Grinding is a totally dust-free process, which helps to minimise disruption to other areas of your building and to your day-to-day operations. Thanks to Industrial Floor Grinding, you can remove old floor coverings, level out the underlying concrete surface and create the perfect environment for your floor to be treated further.

Industrial Floor Joint Repairs

Industrial Flooring Construction Joint Failure is often the greatest source of maintenance problems in Warehouse Flooring or any other Industrial Flooring that sustains continual heavy traffic. Should industrial Floor Joint Repairs or Floor Joint Re-seals not be carried out properly, they can cause serious damage to expensive machinery, such as forklift trucks, and may also become a Health & Safety issue.

Industrial Floor Repairs

Concrete is the composite material of choice for many industrial environments, such as Factory and Warehouse Flooring, and provides a strong, durable platform on which all operations within the building take place. At PSR Industrial Flooring our Industrial Floor Repairs service can ensure that your industrial floor remains at the highest standard, in line with health and safety guidelines.

However, even concrete – one of the strongest materials used in the construction of Industrial Flooring – is susceptible to damage and erosion, which can result in a variety of defects. If your concrete floor is suffering from damage, then you will need to consider industrial floor repairs from the professionals here at PSR Industrial Flooring.

Industrial Floor Screeding

Industrial Floor Screeding is the ideal solution to upgrade or level existing concrete floors. Floor screed can be laid from as little as 3mm thick up to 100mm, and can be used internally as well as externally. We have the capacity to cover up to 1,000m2 per day and most floor screeds we use can be worked within 12 to 24 hours.

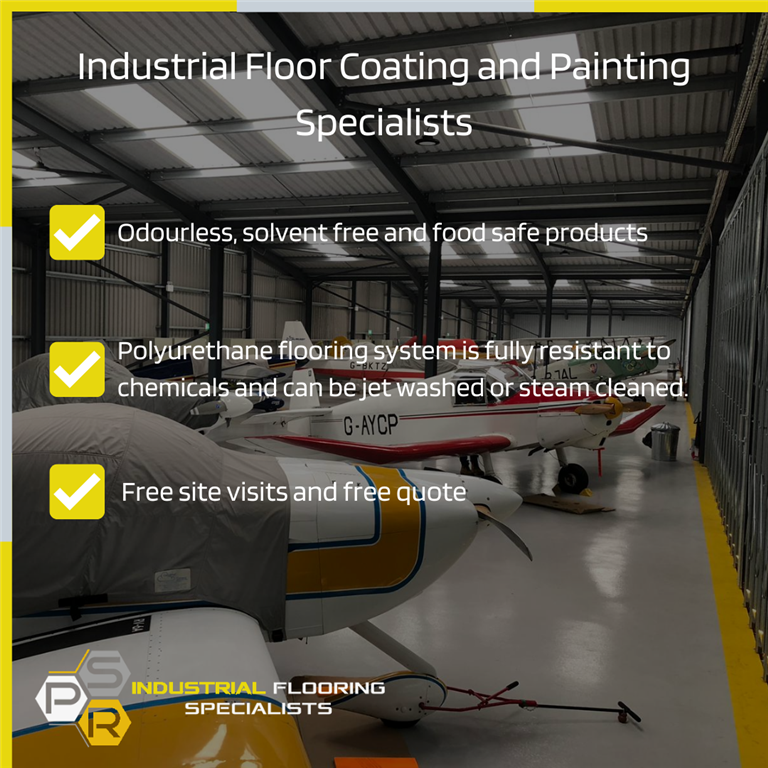

Industrial Floor Coatings

When it comes to industrial floor coating and industrial floor painting services, whether for a small restaurant kitchen or a large warehouse flooring project that requires demarcation, we ensure that we always provide our clients with excellent customer service, as well as living up to our reputation of being reliable and completing industrial floor painting service projects to the highest of standards.

We provide high-quality non-slip industrial floor coating, warehouse floor coatings for walkways and we particularly specialise epoxy high-build, water-dispersible epoxy resin flooring and polyurethane – all of which are available in any RAL or BS colours.

Industrial Resin Flooring

Industrial Resin Flooring has the beneficial properties of being anti-slip and anti-static. As experienced industrial resin flooring contractors, PSR Industrial Resin Flooring can help you bring these advantages to your workplace.

Commercial Resin Flooring has enhanced chemical resistance and is easy to clean and maintain, therefore making this Industrial Resin Flooring Service work particularly well for industries such as catering, healthcare, aviation and marine/offshore environments that require a hardwearing, long-lasting Commercial Resin Floor finish.

Operating worldwide, PSR Industrial Flooring’s practical experience and industrial flooring technical expertise enables us to give you sound advice about your flooring requirements along with a cost-effective, efficient and professional industrial flooring service.

Warehouse Flooring

PSR Industrial Flooring specialises in providing a comprehensive warehouse flooring service, helping to ensure that your floor is of the highest quality and able to easily cope with the constant demands that are present in your warehouse. We pride ourselves on our reliability, outstanding customer service and our quality workmanship and products, so no matter what the requirements of your warehouse may be, PSR Industrial Flooring can provide you with Industrial Floor Expansion Joints to create a durable surface that continues to perform well into the future.

Industrial Floor Grinding

PSR Industrial Flooring provides Industrial Floor Grinding services for a variety of different industrial and commercial environments, working to level out problem floors and offer a more even surface. Concrete Floor Grinding is a totally dust-free process, which helps to minimise disruption to other areas of your building and to your day-to-day operations. Thanks to Industrial Floor Grinding, you can remove old floor coverings, level out the underlying concrete surface and create the perfect environment for your floor to be treated further.

Industrial Floor Joint Repairs

Industrial Flooring Construction Joint Failure is often the greatest source of maintenance problems in Warehouse Flooring or any other Industrial Flooring that sustains continual heavy traffic. Should industrial Floor Joint Repairs or Floor Joint Re-seals not be carried out properly, they can cause serious damage to expensive machinery, such as forklift trucks, and may also become a Health & Safety issue.

Industrial Floor Repairs

Concrete is the composite material of choice for many industrial environments, such as Factory and Warehouse Flooring, and provides a strong, durable platform on which all operations within the building take place. At PSR Industrial Flooring our Industrial Floor Repairs service can ensure that your industrial floor remains at the highest standard, in line with health and safety guidelines.

However, even concrete – one of the strongest materials used in the construction of Industrial Flooring – is susceptible to damage and erosion, which can result in a variety of defects. If your concrete floor is suffering from damage, then you will need to consider industrial floor repairs from the professionals here at PSR Industrial Flooring.

Industrial Floor Screeding

Industrial Floor Screeding is the ideal solution to upgrade or level existing concrete floors. Floor screed can be laid from as little as 3mm thick up to 100mm, and can be used internally as well as externally. We have the capacity to cover up to 1,000m2 per day and most floor screeds we use can be worked within 12 to 24 hours.

Industrial Floor Coatings

When it comes to industrial floor coating and industrial floor painting services, whether for a small restaurant kitchen or a large warehouse flooring project that requires demarcation, we ensure that we always provide our clients with excellent customer service, as well as living up to our reputation of being reliable and completing industrial floor painting service projects to the highest of standards.

We provide high-quality non-slip industrial floor coating, warehouse floor coatings for walkways and we particularly specialise epoxy high-build, water-dispersible epoxy resin flooring and polyurethane – all of which are available in any RAL or BS colours.

Industrial Resin Flooring

Industrial Resin Flooring has the beneficial properties of being anti-slip and anti-static. As experienced industrial resin flooring contractors, PSR Industrial Resin Flooring can help you bring these advantages to your workplace.

Commercial Resin Flooring has enhanced chemical resistance and is easy to clean and maintain, therefore making this Industrial Resin Flooring Service work particularly well for industries such as catering, healthcare, aviation and marine/offshore environments that require a hardwearing, long-lasting Commercial Resin Floor finish.

PSR Industrial Flooring Ltd.

5

out of 5

based on 5 ratings.

Reviews & Testimonials for PSR Industrial Flooring Ltd

We have been working with PSR Industrial Flooring for the last 10 years. During this time, we have worked in collaboration in repairing both our internal and external floors. PSR have understood the demands of our operation and have always been looking at new materials to speed up the repair to be...

July 20, 2018

Testimonial by

David Hopkin, Coca Cola

Testimonial by

David Hopkin, Coca Cola

I found PSR very easy to work with and professional throughout the whole process of refurbishing our warehouse floor. Nothing has been too much trouble for Paul and the contractors performing the works and we were pleased to see that this continued after the job had been completed. We would...

July 01, 2018

Testimonial by

Garth Smithson, Unique Party

Testimonial by

Garth Smithson, Unique Party

Thank you for all your help and communication with bringing our flooring project to a satisfactory conclusion. The team you sent were friendly and professional and have done a very good job so please pass on our thanks to them also"

June 10, 2018

Testimonial by

Celotex

Testimonial by

Celotex

Was recommended this company and wasn’t disappointed. The new flooring looks brilliant and they provided a great service with no hiccups. I will definitely be using PSR again in the future.

2

2

December 07, 2017

Testimonial by

Sami Taylor

Testimonial by

Sami Taylor

The build has gone very well, the team are excellent to work with.

June 01, 2015

Testimonial by

M Millar

Testimonial by

M Millar

Gallery

News

(Read on-line if preferred http://www.benfieldatt.uk/blog/)

Productivity must be top priority

Construction productivity must improve if the industry is to make a success of new infrastructure projects - and Brexit, argues Mark Castle, COO of Mace and Chair of New Build UK. In his view, anyone who has worked in the UK construction sector can't have missed that we have a productivity problem.

Way Behind Europe & Other Industries

"In real terms", he points out, " we haven't improved productivity in decades - and we lag painfully behind our European rivals and other UK industries".

"In the last 10 years, manufacturing output has increased by 50% and by 30% in the service sector – but it hasn't improved at all in construction."

Attitude & Time NOT the Problem

This isn't because our workers work fewer hours, or because our attitudes aren't right - it is in part because we're not adopting new ways of working as quickly as we should. Among the UK's big industries, we lag behind on innovation, research and development, diversity – we're at the back of the queue on so many important metrics that could help us improve.

Unacceptable Position

"It is just not an acceptable position", he states. "Our productivity needs to improve if we're to have a hope of delivering the infrastructure and development we need to keep the UK economy growing sustainably – and indeed to have a hope of making a success of Brexit."

Greater Speed & Efficiency Needed

As asset values peak and we are still experiencing labour and material cost increases then development appraisals are coming under pressure. As an industry we must find ways of delivering projects quicker and more efficiently, otherwise projects will stall as viability will be questioned. We need to come up with ideas on how to do things differently.

Agenda - "Driving Innovation"

As the new chair of Build UK, Castle has made improving productivity and driving innovation a key component of his agenda - one of three priorities for the two years he'll be in post. This includes reforming pre-qualification for procurement. Beyond improving productivity, he aims to reduce costs, improve risk management, drive efficiencies, and evidence high standards by adopting a new common assessment standard to reduce the number of assessment schemes - and increase the transparency and relevance of pre-qualification assessment.

Build on Farmer's Lead

Working with the rest of the team at Build UK, he believes there are many more incremental improvements that collectively will make a really tangible difference to industry productivity. Many of these were laid out by the Farmer report last year, supported by government in its response in July.

Read full opinion

Early Engagement KEY to improving Productivity

While it is often misunderstood, early engagement of Off-Site frame manufacturers produces both better results and greater time savings (typically up to 35%). From early design, through technical development of the structure and manufacturing to transport and erection, our timber based pre-fabrications minimise the need for special equipment and make delivering the affordable high-quality buildings that Architects and their clients want - especially on difficult to access sites.

Empty Shells for "CUSTOM Self-Builds"

Our 'Benfield Homes UK' division is now working with architects & developers to take over the burden of dealing with the latest government planning requirement for 'Custom Self-Build' homes on every development. Observing agreed Design Codes and Plot Passports for planning permissions, our in-house architects and designers use advanced timber frame technology to provide 'empty' shells for 'Custom Self-Builders' to plan and fit out interiors to suit their own ideas. Four stages of completion are offered, from bare shell, with elevations completed, through to 'turnkey' delivery.

PLEASE CONTACT US FOR AN INFORMAL DISCUSSION AS TO HOW WE MIGHT WORK TOGETHER

Call us to arrange a factory visit and discuss your ideas and needs with our in-house team of professionals for your next project. You'll be glad you did!

Productivity must be top priority

Construction productivity must improve if the industry is to make a success of new infrastructure projects - and Brexit, argues Mark Castle, COO of Mace and Chair of New Build UK. In his view, anyone who has worked in the UK construction sector can't have missed that we have a productivity problem.

Way Behind Europe & Other Industries

"In real terms", he points out, " we haven't improved productivity in decades - and we lag painfully behind our European rivals and other UK industries".

"In the last 10 years, manufacturing output has increased by 50% and by 30% in the service sector – but it hasn't improved at all in construction."

Attitude & Time NOT the Problem

This isn't because our workers work fewer hours, or because our attitudes aren't right - it is in part because we're not adopting new ways of working as quickly as we should. Among the UK's big industries, we lag behind on innovation, research and development, diversity – we're at the back of the queue on so many important metrics that could help us improve.

Unacceptable Position

"It is just not an acceptable position", he states. "Our productivity needs to improve if we're to have a hope of delivering the infrastructure and development we need to keep the UK economy growing sustainably – and indeed to have a hope of making a success of Brexit."

Greater Speed & Efficiency Needed

As asset values peak and we are still experiencing labour and material cost increases then development appraisals are coming under pressure. As an industry we must find ways of delivering projects quicker and more efficiently, otherwise projects will stall as viability will be questioned. We need to come up with ideas on how to do things differently.

Agenda - "Driving Innovation"

As the new chair of Build UK, Castle has made improving productivity and driving innovation a key component of his agenda - one of three priorities for the two years he'll be in post. This includes reforming pre-qualification for procurement. Beyond improving productivity, he aims to reduce costs, improve risk management, drive efficiencies, and evidence high standards by adopting a new common assessment standard to reduce the number of assessment schemes - and increase the transparency and relevance of pre-qualification assessment.

Build on Farmer's Lead

Working with the rest of the team at Build UK, he believes there are many more incremental improvements that collectively will make a really tangible difference to industry productivity. Many of these were laid out by the Farmer report last year, supported by government in its response in July.

Read full opinion

Early Engagement KEY to improving Productivity

While it is often misunderstood, early engagement of Off-Site frame manufacturers produces both better results and greater time savings (typically up to 35%). From early design, through technical development of the structure and manufacturing to transport and erection, our timber based pre-fabrications minimise the need for special equipment and make delivering the affordable high-quality buildings that Architects and their clients want - especially on difficult to access sites.

Empty Shells for "CUSTOM Self-Builds"

Our 'Benfield Homes UK' division is now working with architects & developers to take over the burden of dealing with the latest government planning requirement for 'Custom Self-Build' homes on every development. Observing agreed Design Codes and Plot Passports for planning permissions, our in-house architects and designers use advanced timber frame technology to provide 'empty' shells for 'Custom Self-Builders' to plan and fit out interiors to suit their own ideas. Four stages of completion are offered, from bare shell, with elevations completed, through to 'turnkey' delivery.

PLEASE CONTACT US FOR AN INFORMAL DISCUSSION AS TO HOW WE MIGHT WORK TOGETHER

Call us to arrange a factory visit and discuss your ideas and needs with our in-house team of professionals for your next project. You'll be glad you did!

Scotland

Scotland UK

UK Ireland

Ireland London

London