Address

Derwent House

42-46 Waterloo Road

42-46 Waterloo Road

Wolverhampton

West Midlands

WV1 4XB

England UK

About Membracon UK Limited

We are market leaders in technology for process filtration and water treatment within Aerospace, Automotive, Food & Beverage, Pharmaceutical and Finishing sectors Worldwide.

OUR SERVICES

OUR SERVICES

- Complete System Review

- Maintenance & Service

- Free Plant Health Check

- Anode Solutions For Electrocoating

- UF Membranes For Water & Electrocoating

- AC-DC Rectifier Coating Applications

- Chemical Process Tank Integrity Check

- Reverse Osmosis Membranes & Systems

- UV Bacterial Prevention Solutions For Water

- Liquid Filtration Solutions Bags Cartridges

- Ceramic Membrane Filtration Sanitary Effluent

- Industrial Waste Water Effluent Treatment

Gallery

News

The application of membrane technologies for water and wastewater treatment is growing due to tighter regulations for water quality.

It’s important to understand the benefits reverse osmosis can provide to industrial processes and why it’s one of the best water filtration systems. Focusing on environmental, cost, health and safety and maintenance benefits.

What is Reverse Osmosis (RO)?

It’s a process in which raw water passes through a system that removes impurities. Raw water has not been treated or had any elements removed.

The water comes into the system via a break tank or mains feed. The quality of the incoming water differs with geographic location.

A high-pressure pump drives the water through a set of membranes. A membrane is a selective barrier. As water passes through it, impurities such as salt or solids are removed.

This process improves the purity and quality of the incoming water supply, by reducing the

micro-Siemens and total dissolved solids (TDS).

Membracon offer a wide range of RO systems and replacement membranes. They also provide

pre-treatment equipment including softeners, activated carbon filters, and multimedia filters; that remove a wide range of Impurities.

Environmental Benefits

One of the main environmental benefits of using a Reverse osmosis system is less hazardous wastewater. This is due to not requiring any harmful chemicals within the process of producing the permeate (pure water).

Reverse osmosis is one of the greenest solutions for industrial wastewater.

Another environmental benefit of RO is the capture and correct disposal of impurities within the mains water feed. This is without the discharge of harmful chemically saturated water going to effluent or drain.

Our cutting edge design of the membranes removes the impurities from the water feed without the use of chemicals, resins, or ion exchange beds.

At the end of the life of chemical-based systems, the removal and disposal of the resins and ion exchange beds have a huge environmental impact in comparison to a membrane system.

Concentrated impurities from an RO System can then be discharged directly to drain without the need for a further costly effluent treatment process.

Cost Benefits

Prices for acid and caustic solutions continue to rise while the costs of using reverse osmosis and membrane elements are decreasing.

The primary cost of reverse-osmosis systems is electricity. Modern water filtration systems consume little energy so operating costs are relatively low.

An RO system can be installed into the process and feed directly into the production line or to a holding tank for storage and then use as required.

Wastewater streams can run through an RO system aiding in a reduction of disposal costs via reuse back into the process.

Health and Safety Benefits

The main health and safety benefits of using a reverse osmosis system to produce high-quality water are there are no hazardous chemicals required.

Traditional resin-based ion exchange systems use highly dangerous acids and alkalis.

Reverse osmosis replaces conventional processes like chemical treatment with smaller and more efficient equipment.

By doing this it eliminates the opposing risks of manual handling and the possession of hazardous chemicals on-site, providing a safer working environment for the personnel.

Maintenance Benefits

The RO system is extremely maintenance-friendly as it is a self-contained unit.

It self-cleans and requires minimal operator interaction. It only requires daily monitoring from on-site personnel rather than being actively maintained.

This maintains productivity with limited downtime needed.

Changing the pre-filters is ergonomically friendly and can be completed within minutes.

The membranes can last 2-3 years, depending on varying factors such as the quality and quantity of feed water.

100% of membranes within a given system could be replaced within hours, compared to a resin-based system which could take days.

Membracon can provide comprehensive service & maintenance package along with a finance solution to suit you.

Conclusion

With such advantages and benefits, the use of reverse osmosis across industry sectors is set to increase. It opposes less risk to staff, is more efficient, cost-effective, environmentally friendly and requires low maintenance.

Reverse osmosis can also be used commercially as well as in industrial processes.

It’s important to understand the benefits reverse osmosis can provide to industrial processes and why it’s one of the best water filtration systems. Focusing on environmental, cost, health and safety and maintenance benefits.

What is Reverse Osmosis (RO)?

It’s a process in which raw water passes through a system that removes impurities. Raw water has not been treated or had any elements removed.

The water comes into the system via a break tank or mains feed. The quality of the incoming water differs with geographic location.

A high-pressure pump drives the water through a set of membranes. A membrane is a selective barrier. As water passes through it, impurities such as salt or solids are removed.

This process improves the purity and quality of the incoming water supply, by reducing the

micro-Siemens and total dissolved solids (TDS).

Membracon offer a wide range of RO systems and replacement membranes. They also provide

pre-treatment equipment including softeners, activated carbon filters, and multimedia filters; that remove a wide range of Impurities.

Environmental Benefits

One of the main environmental benefits of using a Reverse osmosis system is less hazardous wastewater. This is due to not requiring any harmful chemicals within the process of producing the permeate (pure water).

Reverse osmosis is one of the greenest solutions for industrial wastewater.

Another environmental benefit of RO is the capture and correct disposal of impurities within the mains water feed. This is without the discharge of harmful chemically saturated water going to effluent or drain.

Our cutting edge design of the membranes removes the impurities from the water feed without the use of chemicals, resins, or ion exchange beds.

At the end of the life of chemical-based systems, the removal and disposal of the resins and ion exchange beds have a huge environmental impact in comparison to a membrane system.

Concentrated impurities from an RO System can then be discharged directly to drain without the need for a further costly effluent treatment process.

Cost Benefits

Prices for acid and caustic solutions continue to rise while the costs of using reverse osmosis and membrane elements are decreasing.

The primary cost of reverse-osmosis systems is electricity. Modern water filtration systems consume little energy so operating costs are relatively low.

An RO system can be installed into the process and feed directly into the production line or to a holding tank for storage and then use as required.

Wastewater streams can run through an RO system aiding in a reduction of disposal costs via reuse back into the process.

Health and Safety Benefits

The main health and safety benefits of using a reverse osmosis system to produce high-quality water are there are no hazardous chemicals required.

Traditional resin-based ion exchange systems use highly dangerous acids and alkalis.

Reverse osmosis replaces conventional processes like chemical treatment with smaller and more efficient equipment.

By doing this it eliminates the opposing risks of manual handling and the possession of hazardous chemicals on-site, providing a safer working environment for the personnel.

Maintenance Benefits

The RO system is extremely maintenance-friendly as it is a self-contained unit.

It self-cleans and requires minimal operator interaction. It only requires daily monitoring from on-site personnel rather than being actively maintained.

This maintains productivity with limited downtime needed.

Changing the pre-filters is ergonomically friendly and can be completed within minutes.

The membranes can last 2-3 years, depending on varying factors such as the quality and quantity of feed water.

100% of membranes within a given system could be replaced within hours, compared to a resin-based system which could take days.

Membracon can provide comprehensive service & maintenance package along with a finance solution to suit you.

Conclusion

With such advantages and benefits, the use of reverse osmosis across industry sectors is set to increase. It opposes less risk to staff, is more efficient, cost-effective, environmentally friendly and requires low maintenance.

Reverse osmosis can also be used commercially as well as in industrial processes.

Industrial processes use high quantities of water, offering major cost savings and environmental benefits to businesses using modern wastewater treatment and recycling solutions.

Tighter environmental regulations also create serious challenges to businesses using high volumes of water in their production processes, as breaching these regulations can lead to heavy fines and bad publicity.

The Cost of Poor Water Treatment Management

Fines in 2017 average over £440,000. With the added risk of 5 years imprisonment, improving your wastewater treatment by investing in a better solution should be a serious consideration for your businesses security.

2018 saw a West Midlands company fined £180,000 for incorrectly disposing of chemicals. Breaching limits for cyanide, zinc and chemical oxygen demand and by not adhering to the Environmental Permitting Regulations 2010.

Membrane technologies in industrial wastewater treatment are becoming increasingly popular with companies seeking a sustainable and reliable solution to improving the way they manage wastewater.

What is Industrial Wastewater Treatment?

Industrial wastewater treatment is the process used to convert wastewater into the treated water. This can then be returned to the water cycle with minimum impact on the environment or directly reused in production.

Dependent on the quality of water in your location, different wastewater solutions can be implemented.

There are various solutions such as;

Reverse Osmosis (RO)

Water Recycling units

Ceramic Filtration

Ultrafiltration

Nanofiltration

Coarse Filtration

UV light

Reverse osmosis is becoming an increasingly popular choice of wastewater treatment due to the many benefits it has including its green solution.

How Can Industrial Wastewater Treatment Help The Environment?

When used in the industrial process, wastewater solutions can help the environment by removing hazardous chemicals before allowing the water to go to drain. The quantities of water used industrially are huge, burdening organisations with the social responsibility of ensuring it’s managed correctly.

Take the automotive industry as an example, to produce one small car it requires half a million litres of water. There is an average of 70 million cars produced globally every year, that’s over 35 trillion litres of water from the automotive sector in one year alone.

Wastewater produced from manufacturing a car can contain metals, oils, grease and harmful chemicals from paint residue. These products can cause long-term damage to the environment and can be dangerous if they enter the main water system.

Greenpeace state that dangerous chemicals not only threaten our environment but the health of all living beings. New-born babies are entering the world contaminated with poisonous chemicals inherited from their mothers. Proving that the slow accumulation of hazardous substances in the environment, food chain and our bodies is a serious problem.

This is where wastewater treatment comes in, introducing a wastewater treatment system can remove these products. This allows the water to be reused in production or re-enter the water cycle safely.

Modern wastewater solutions use membrane technology. The cutting edge design of membranes removes the impurities from the water feed without the use of chemicals, resins, or ion exchange beds.

Conclusion

As society becomes more eco-conscious, more companies are looking for greener ways to manufacture their products. The punishments for not complying aren’t worth the risk the damage it imposes on your company’s reputation.

Membrane technology is the future of correctly treating and managing wastewater. The cost and environmental benefits of implementing these systems are converting more companies than ever before.

Find out how you can benefit too by getting in touch today. Membracon tailors each system to suit each clients water issue, with every unit designed and built fully bespoke to you. Membracon offer a free water test analysis to help identify your water issue.

Tighter environmental regulations also create serious challenges to businesses using high volumes of water in their production processes, as breaching these regulations can lead to heavy fines and bad publicity.

The Cost of Poor Water Treatment Management

Fines in 2017 average over £440,000. With the added risk of 5 years imprisonment, improving your wastewater treatment by investing in a better solution should be a serious consideration for your businesses security.

2018 saw a West Midlands company fined £180,000 for incorrectly disposing of chemicals. Breaching limits for cyanide, zinc and chemical oxygen demand and by not adhering to the Environmental Permitting Regulations 2010.

Membrane technologies in industrial wastewater treatment are becoming increasingly popular with companies seeking a sustainable and reliable solution to improving the way they manage wastewater.

What is Industrial Wastewater Treatment?

Industrial wastewater treatment is the process used to convert wastewater into the treated water. This can then be returned to the water cycle with minimum impact on the environment or directly reused in production.

Dependent on the quality of water in your location, different wastewater solutions can be implemented.

There are various solutions such as;

Reverse Osmosis (RO)

Water Recycling units

Ceramic Filtration

Ultrafiltration

Nanofiltration

Coarse Filtration

UV light

Reverse osmosis is becoming an increasingly popular choice of wastewater treatment due to the many benefits it has including its green solution.

How Can Industrial Wastewater Treatment Help The Environment?

When used in the industrial process, wastewater solutions can help the environment by removing hazardous chemicals before allowing the water to go to drain. The quantities of water used industrially are huge, burdening organisations with the social responsibility of ensuring it’s managed correctly.

Take the automotive industry as an example, to produce one small car it requires half a million litres of water. There is an average of 70 million cars produced globally every year, that’s over 35 trillion litres of water from the automotive sector in one year alone.

Wastewater produced from manufacturing a car can contain metals, oils, grease and harmful chemicals from paint residue. These products can cause long-term damage to the environment and can be dangerous if they enter the main water system.

Greenpeace state that dangerous chemicals not only threaten our environment but the health of all living beings. New-born babies are entering the world contaminated with poisonous chemicals inherited from their mothers. Proving that the slow accumulation of hazardous substances in the environment, food chain and our bodies is a serious problem.

This is where wastewater treatment comes in, introducing a wastewater treatment system can remove these products. This allows the water to be reused in production or re-enter the water cycle safely.

Modern wastewater solutions use membrane technology. The cutting edge design of membranes removes the impurities from the water feed without the use of chemicals, resins, or ion exchange beds.

Conclusion

As society becomes more eco-conscious, more companies are looking for greener ways to manufacture their products. The punishments for not complying aren’t worth the risk the damage it imposes on your company’s reputation.

Membrane technology is the future of correctly treating and managing wastewater. The cost and environmental benefits of implementing these systems are converting more companies than ever before.

Find out how you can benefit too by getting in touch today. Membracon tailors each system to suit each clients water issue, with every unit designed and built fully bespoke to you. Membracon offer a free water test analysis to help identify your water issue.

Industrial wastewater is a major culprit of water pollution. This is because companies are disposing of wastewater incorrectly without treating or managing it first. Reverse osmosis purifies the wastewater before it goes to drain, making for a green water solution that meets water regulations.

RO uses no chemicals to treat wastewater, just cleverly designed membranes. Help Save Nature advises that large-scale industries operate their own on-site treatment systems to reduce the number of pollutants, such as RO.

How Is Reverse Osmosis Used In The Industrial Process?

An RO system can be installed in the production line of any manufacturing process that requires precise water. As raw water enters the system from either a break tank or mains feed, high-pressure pumps drive the water through a set of membranes.

These membranes are selective barriers that capture impurities such as salts, or solids. Each RO system is installed with specific membranes to remove the relevant impurities, these are dependent on the quality of water at your location.

The water leaves the RO system as clean water, ready to be used in production. Used frequently in pharmaceutical pure water systems due to its capability of rejecting 99.9% of bacteria.

Finishing processes in the automotive and aerospace industries require precise water specifications to ensure the highest quality of the production parts. This precision is easily achieved with RO as systems are designed bespoke to the water quality you want to achieve for your process.

Why Is RO A Green Solution To Industrial Water Treatment?

Reverse osmosis is a modern solution to wastewater treatment. The cutting edge spiral design of membranes remove the impurities from the water feed without the use of chemicals, resins, or ion exchange beds.

Wastewater produced from manufacturing can be contaminated with damaging products. For instance, the wastewater created from producing a car can include metals, oils, grease and harmful chemicals from paint residue.

If this wastewater was to re-enter the water cycle without the correct treatment it could cause long-term damage to the environment.

Reverse osmosis removes certain impurities allowing you to reuse the water in the production process or release the water to drain without causing any harm to the environment.

Water pollution is also harming animals, killing fish that then have a knock-on effect on the food pyramid as a whole.

As the industrial sector contributes heavily to the quantity of harmful wastewater that re-enters the water cycle, it’s their corporate social responsibility to prevent it.

Society is becoming more eco-conscious, with companies using this to their advantage by generating green campaigns and improving the way they manufacture products.

Poor water treatment management can incur high fines and serious punishments such as the imprisonment of the managing director of the business that fails to meet regulations.

RO systems are self-cleaning, self-contained units that look after themselves. They are powered by electricity and only require a daily check from onsite personnel.

Conclusion

Introducing RO as an industrial wastewater solution is a greener alternative to using harmful chemicals. The combination of pressure and uniquely designed membrane systems remove harmful products so water can re-enter the water cycle safely, or even be reused in production.

RO has many benefits with its huge environmental factor being just one of them. As society becomes more aware of issues such as water pollution, laws and regulations are expected to become tighter.

Reverse osmosis can also be used commercially.

All water filtration systems are tailored to each clients water issue. Membracon design and build every unit fully bespoke to suit each customers requirements. The first step is to analyse your raw water, Membracon offers a free water analysis test to help you with this process. Please contact us to arrange today.

RO uses no chemicals to treat wastewater, just cleverly designed membranes. Help Save Nature advises that large-scale industries operate their own on-site treatment systems to reduce the number of pollutants, such as RO.

How Is Reverse Osmosis Used In The Industrial Process?

An RO system can be installed in the production line of any manufacturing process that requires precise water. As raw water enters the system from either a break tank or mains feed, high-pressure pumps drive the water through a set of membranes.

These membranes are selective barriers that capture impurities such as salts, or solids. Each RO system is installed with specific membranes to remove the relevant impurities, these are dependent on the quality of water at your location.

The water leaves the RO system as clean water, ready to be used in production. Used frequently in pharmaceutical pure water systems due to its capability of rejecting 99.9% of bacteria.

Finishing processes in the automotive and aerospace industries require precise water specifications to ensure the highest quality of the production parts. This precision is easily achieved with RO as systems are designed bespoke to the water quality you want to achieve for your process.

Why Is RO A Green Solution To Industrial Water Treatment?

Reverse osmosis is a modern solution to wastewater treatment. The cutting edge spiral design of membranes remove the impurities from the water feed without the use of chemicals, resins, or ion exchange beds.

Wastewater produced from manufacturing can be contaminated with damaging products. For instance, the wastewater created from producing a car can include metals, oils, grease and harmful chemicals from paint residue.

If this wastewater was to re-enter the water cycle without the correct treatment it could cause long-term damage to the environment.

Reverse osmosis removes certain impurities allowing you to reuse the water in the production process or release the water to drain without causing any harm to the environment.

Water pollution is also harming animals, killing fish that then have a knock-on effect on the food pyramid as a whole.

As the industrial sector contributes heavily to the quantity of harmful wastewater that re-enters the water cycle, it’s their corporate social responsibility to prevent it.

Society is becoming more eco-conscious, with companies using this to their advantage by generating green campaigns and improving the way they manufacture products.

Poor water treatment management can incur high fines and serious punishments such as the imprisonment of the managing director of the business that fails to meet regulations.

RO systems are self-cleaning, self-contained units that look after themselves. They are powered by electricity and only require a daily check from onsite personnel.

Conclusion

Introducing RO as an industrial wastewater solution is a greener alternative to using harmful chemicals. The combination of pressure and uniquely designed membrane systems remove harmful products so water can re-enter the water cycle safely, or even be reused in production.

RO has many benefits with its huge environmental factor being just one of them. As society becomes more aware of issues such as water pollution, laws and regulations are expected to become tighter.

Reverse osmosis can also be used commercially.

All water filtration systems are tailored to each clients water issue. Membracon design and build every unit fully bespoke to suit each customers requirements. The first step is to analyse your raw water, Membracon offers a free water analysis test to help you with this process. Please contact us to arrange today.

Modern membrane technologies allow for the treatment of industrial wastewater solutions to be managed by an all in one system.

Dependent on the water issue and the quality of water you want to achieve, multiple units can be combined to create a bespoke water solution for your industrial process.

Industrial wastewater is mainly treated through the use of membranes; as water passes through, impurities are captured, leaving you with clean water to re-enter the water cycle or reuse in production.

More traditional treatments include the use of harsh chemicals; rising costs and growing health and safety hazards are seeing a decline in these methods.

What Industrial Wastewater Treatments Are Available?

There are a variety of wastewater treatments available for industrial processes, sometimes a combination of systems are put in place dependent on the water issue.

Wastewater treatments used in industrial processes:

Reverse Osmosis (RO)

Water Recycling Units

Ceramic Filtration

Ultrafiltration

Nanofiltration

Coarse Filtration

UV Light

Reverse Osmosis

Reverse osmosis is becoming increasingly popular in wastewater management within the industrial process due to the many benefits it has. It's capable of rejecting 99.9% of bacteria, making it ideal for the use in pharmaceuticals pure water systems.

RO systems manage wastewater and themselves, as they are self-containing self-cleaning units. RO treats wastewater by using pressure to make the water pass through semi-permeable membranes, removing impurities as it passes.

Its doesn’t use any chemicals and requires very little maintenance, just a daily check by onsite personnel. Making RO an incredibly sustainable and green option for industrial wastewater management.

RO is already being used heavily in the automotive and aerospace industry in finishing processes to achieve precise water specifications to ensure the highest quality of the production parts.

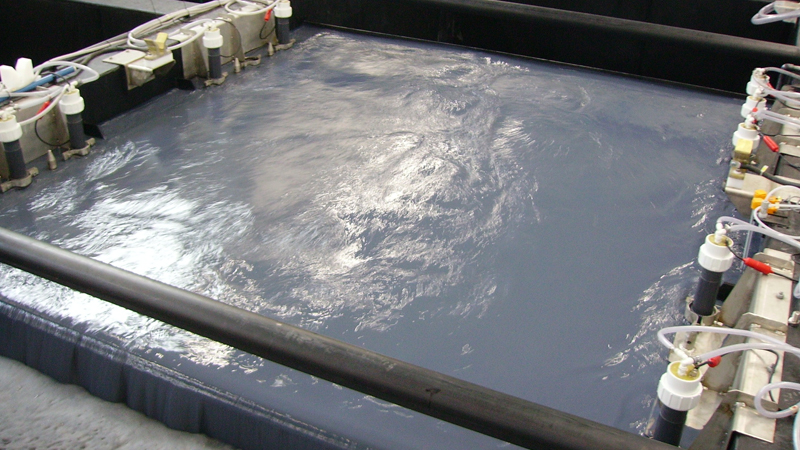

Water Recycling Units & Ceramic Filtration

Water recycling units use ceramic membranes as they are able to provide filtration at high flows, whilst minimising membrane fouling.

They have the ability to be regenerated via a wide range of chemical and chemical cleaning conditions than the more conventional spiral and hollow fibre membranes.

The ceramic material allows them to filter fluids with a high concentration of oils, suspended solids and high viscosity.

Water recycling units are designed to assist Membrane Bio-Reactor (MBR) systems, which is a biological wastewater treatment process coupled to a membrane filtration system.

Ultrafiltration

Ultrafiltration spiral membranes are ideal for most concentration or clarification applications. Their construction suits a broad range of chemical, temperature and pressure applications.

They are energy-efficient, compact and economical to install, making them ideal for wastewater management in industrial processes.

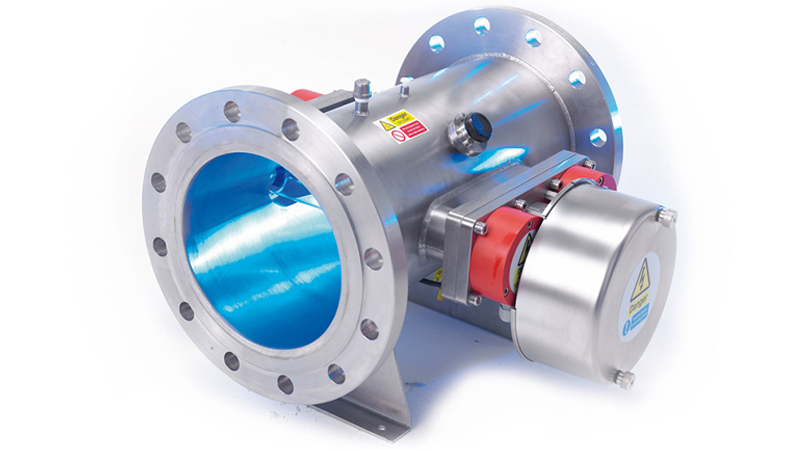

UV Light

UV light wastewater treatment is used for bacterial control ensuring organisms are unable to replicate. They have a typical life of only a few minutes, making them harmless.

UV treatment does not affect the colour, taste or pH of the water. It can be used to remove chlorine, chloramines, ozone, bromine and a wide variety of organic contaminants, making them ideal for treating industrial wastewater.

Conclusion

There are a variety of systems that will manage and treat your industrial wastewater; units are tailored to each clients water issue.

Tighter regulations and harsher fines call for industrial companies to improve the way they treat and dispose of wastewater.

Environmental awareness is also increasing with the industrial sector being the biggest culprit of incorrectly treated wastewater.

Membracon design and build every unit fully bespoke to suit each customers requirements. The first step is to analyse your raw water, Membracon offers a free water analysis test to help you with this process. Please contact us to arrange today.

Dependent on the water issue and the quality of water you want to achieve, multiple units can be combined to create a bespoke water solution for your industrial process.

Industrial wastewater is mainly treated through the use of membranes; as water passes through, impurities are captured, leaving you with clean water to re-enter the water cycle or reuse in production.

More traditional treatments include the use of harsh chemicals; rising costs and growing health and safety hazards are seeing a decline in these methods.

What Industrial Wastewater Treatments Are Available?

There are a variety of wastewater treatments available for industrial processes, sometimes a combination of systems are put in place dependent on the water issue.

Wastewater treatments used in industrial processes:

Reverse Osmosis (RO)

Water Recycling Units

Ceramic Filtration

Ultrafiltration

Nanofiltration

Coarse Filtration

UV Light

Reverse Osmosis

Reverse osmosis is becoming increasingly popular in wastewater management within the industrial process due to the many benefits it has. It's capable of rejecting 99.9% of bacteria, making it ideal for the use in pharmaceuticals pure water systems.

RO systems manage wastewater and themselves, as they are self-containing self-cleaning units. RO treats wastewater by using pressure to make the water pass through semi-permeable membranes, removing impurities as it passes.

Its doesn’t use any chemicals and requires very little maintenance, just a daily check by onsite personnel. Making RO an incredibly sustainable and green option for industrial wastewater management.

RO is already being used heavily in the automotive and aerospace industry in finishing processes to achieve precise water specifications to ensure the highest quality of the production parts.

Water Recycling Units & Ceramic Filtration

Water recycling units use ceramic membranes as they are able to provide filtration at high flows, whilst minimising membrane fouling.

They have the ability to be regenerated via a wide range of chemical and chemical cleaning conditions than the more conventional spiral and hollow fibre membranes.

The ceramic material allows them to filter fluids with a high concentration of oils, suspended solids and high viscosity.

Water recycling units are designed to assist Membrane Bio-Reactor (MBR) systems, which is a biological wastewater treatment process coupled to a membrane filtration system.

Ultrafiltration

Ultrafiltration spiral membranes are ideal for most concentration or clarification applications. Their construction suits a broad range of chemical, temperature and pressure applications.

They are energy-efficient, compact and economical to install, making them ideal for wastewater management in industrial processes.

UV Light

UV light wastewater treatment is used for bacterial control ensuring organisms are unable to replicate. They have a typical life of only a few minutes, making them harmless.

UV treatment does not affect the colour, taste or pH of the water. It can be used to remove chlorine, chloramines, ozone, bromine and a wide variety of organic contaminants, making them ideal for treating industrial wastewater.

Conclusion

There are a variety of systems that will manage and treat your industrial wastewater; units are tailored to each clients water issue.

Tighter regulations and harsher fines call for industrial companies to improve the way they treat and dispose of wastewater.

Environmental awareness is also increasing with the industrial sector being the biggest culprit of incorrectly treated wastewater.

Membracon design and build every unit fully bespoke to suit each customers requirements. The first step is to analyse your raw water, Membracon offers a free water analysis test to help you with this process. Please contact us to arrange today.

Commercial ultrafiltration uses standard low pressure to push water through a membrane to filter out contaminants, bacteria, viruses and parasites whilst retaining minerals in the water.

Ultrafiltration is implemented commercially in a variety of ways, small kits can be installed under your sink at home to improve the quality of drinking water from your tap.

It’s also used on a much larger scale providing remote villages, who otherwise wouldn’t have access to, clean drinking water.

What Is Ultrafiltration?

Ultrafiltration (UF) is a membrane filtration process similar to reverse osmosis, using pressure to force water through a semi-permeable membrane.

However, ultrafiltration systems operate with low-pressure water.

The primary task of an ultrafiltration system is to remove the substances which contribute to the taste, colour and odour of the water.

Ultrafiltration removes contaminants and harmful bacteria whilst only freshwater and dissolved minerals pass through.

A UF membrane is a fine filter that reduces particles 5,000 times smaller than a human hair.

How Does Ultrafiltration Work Commercially?

Drinking water is the most popular way ultrafiltration is used commercially, many companies produce water filters that can be fitted under the sink, providing a family with filtered water.

Ultrafiltration can also be used on a larger scale such as providing solutions to drinking water problems in remote interior areas across India.

The implementation of ultrafiltration in remote areas can have huge benefits to the people, creating social harmony and strengthening society from within.

The use of ultrafiltration will have greater benefits to the people in remote areas in countries that are known for poor water quality compared to someone in an established country installing a system when they already have drinkable water available on tap.

What Advantages Are There To Using Ultrafiltration?

The process of ultrafiltration is extremely environmentally friendly, with little resources needed to function, this is what makes it the ideal solution for commercial use, where materials and energy are scarce.

It can also be used as a pre-treatment to other water treatment solutions or as a final filtration stage for deionized water.

Advantages To Commercial Ultrafiltration:

Requires no chemicals

Performs at low pressure

Ideal for temperature-sensitive materials

Membranes come in different sizes

Needs no electricity to function

Environment cautious process

Cost-effective

Conclusion

Overall Ultrafiltration is the most suited water treatment solution to be used commercially due to the many advantages it has. Its environmentally friendly design means it requires no chemicals, energy or high pressure to function, which many remote areas in undeveloped countries are without.

The simple process of capturing contaminants, bacteria, parasites and viruses whilst retaining minerals in the water makes it the ideal treatment for drinking water.

Membracon design and build every water treatment solution bespoke to each customer's requirements. The first step is to analyse your raw water to see if Ultrafiltration is the best solution for you.

Membracon offers a free water analysis test to help you understand your water issue in more detail. Get in touch to arrange today.

Ultrafiltration is implemented commercially in a variety of ways, small kits can be installed under your sink at home to improve the quality of drinking water from your tap.

It’s also used on a much larger scale providing remote villages, who otherwise wouldn’t have access to, clean drinking water.

What Is Ultrafiltration?

Ultrafiltration (UF) is a membrane filtration process similar to reverse osmosis, using pressure to force water through a semi-permeable membrane.

However, ultrafiltration systems operate with low-pressure water.

The primary task of an ultrafiltration system is to remove the substances which contribute to the taste, colour and odour of the water.

Ultrafiltration removes contaminants and harmful bacteria whilst only freshwater and dissolved minerals pass through.

A UF membrane is a fine filter that reduces particles 5,000 times smaller than a human hair.

How Does Ultrafiltration Work Commercially?

Drinking water is the most popular way ultrafiltration is used commercially, many companies produce water filters that can be fitted under the sink, providing a family with filtered water.

Ultrafiltration can also be used on a larger scale such as providing solutions to drinking water problems in remote interior areas across India.

The implementation of ultrafiltration in remote areas can have huge benefits to the people, creating social harmony and strengthening society from within.

The use of ultrafiltration will have greater benefits to the people in remote areas in countries that are known for poor water quality compared to someone in an established country installing a system when they already have drinkable water available on tap.

What Advantages Are There To Using Ultrafiltration?

The process of ultrafiltration is extremely environmentally friendly, with little resources needed to function, this is what makes it the ideal solution for commercial use, where materials and energy are scarce.

It can also be used as a pre-treatment to other water treatment solutions or as a final filtration stage for deionized water.

Advantages To Commercial Ultrafiltration:

Requires no chemicals

Performs at low pressure

Ideal for temperature-sensitive materials

Membranes come in different sizes

Needs no electricity to function

Environment cautious process

Cost-effective

Conclusion

Overall Ultrafiltration is the most suited water treatment solution to be used commercially due to the many advantages it has. Its environmentally friendly design means it requires no chemicals, energy or high pressure to function, which many remote areas in undeveloped countries are without.

The simple process of capturing contaminants, bacteria, parasites and viruses whilst retaining minerals in the water makes it the ideal treatment for drinking water.

Membracon design and build every water treatment solution bespoke to each customer's requirements. The first step is to analyse your raw water to see if Ultrafiltration is the best solution for you.

Membracon offers a free water analysis test to help you understand your water issue in more detail. Get in touch to arrange today.

The main difference between microfiltration, nanofiltration and ultrafiltration is the pore size of the membrane. With each different filtration process, a variety of elements get either blocked or pass through with the water. Below is a diagram to demonstrate this.

Reverse osmosis is the only water filtration procedure to remove all elements completely, leaving just pure water, proving popular in the pharmaceuticals sector.

Each filtration process has the same procedure, water passes through a semipermeable membrane, depending on the pore size certain elements are removed whilst others pass through.

The correct filtration process is selected specifically for your individual water issue.

What Is Microfiltration (MF)?

Microfiltration is the process of physically removing suspended solids from water, through a membrane. Microfiltration is often used in conjunction with other separation processes such as ultrafiltration and reverse osmosis.

The filters used in microfiltration have a pore size of approximately 0.1 microns (small). Bacteria and suspended solids are the only elements that can be removed through microfiltration.

A typical use for an ultrafiltration system can be:

A pre-treatment for another water treatment process

Certain types of effluent treatment

Certain oil and water separation applications

Treat wastewater

Sterilizing beverages and pharmaceuticals without sacrificing flavour

Processing dairy products while allowing protein through.

What Is Ultrafiltration (UF)?

Ultrafiltration blocks everything microfiltration can with the addition of viruses, requiring a slightly higher pressure to achieve this.

Although it requires higher pressure than MF, ultrafiltration can be powered by the pressure you get from the tap, making it popular in the commercial sector for drinking water.

It works the same way as MF by which a contaminated liquid passes through a membrane that is too large to fit through the membranes pore sizes, yielding a purified liquid stream.

Ultrafiltration filters have a pore size of approximately 0.01 micron (smaller).

UF can be used in the following processes:

Treating wastewater

Concentrating proteins

Chemical process separation

Separating oil/water emulsions

Removing pathogens from milk

Clarifying fruit juices

What Is Nanofiltration (NF)?

Nanofiltration membranes typically remove 50% – 90% of monovalent ions such as chlorides or sodium.

The design and operation of the filters used in NF are very similar to that of reverse osmosis, with some differences. Those being the membrane isn’t as ‘tight’ as RO membranes and a lower feedwater pressure is required.

Nanofiltration filters have a pore size of approximately 0.001 micron (smallest).

It has attained the name of the ‘softening membrane’ as it is often used to filter water with low amounts of total dissolved solids, to remove organic matter and to soften water.

NF can be used in the following processes:

Water treatment

Pre-treatment for RO

Pharmaceuticals

Textiles

Bakeries

Dairy

What’s The Difference Between Micro, Nano And Ultra-Filtration?

Ultimately they all do the same job but remove different elements depending on the water issue and the industry using it.

The pore size of the semipermeable membranes used is the only major difference between microfiltration, nanofiltration and ultrafiltration.

The different pore sizes allow for different elements allowed to be passed through, giving ultimate precision to treating your wastewater issue correctly and safely for the environment.

To remove all impurities all together, reverse osmosis is used. With tighter regulations and the many benefits it has, RO is becoming increasingly popular in the industrial sector.

Dependent on your water issue, microfiltration, ultrafiltration and nanofiltration may be used to purify and help you manage and treat your wastewater.

Each water issue is treated separately and a bespoke system is designed and built to reach the quality of water you want to achieve for your process.

A combination of more than one system is common to achieve such a precise quality of the water where regulations are tighter.

The first step to achieving your water solution is to understand the issues within your water. Membracon offers a free water analysis test to help you with this process, combined with expert knowledge to help and advise you through your project.

Reverse osmosis is the only water filtration procedure to remove all elements completely, leaving just pure water, proving popular in the pharmaceuticals sector.

Each filtration process has the same procedure, water passes through a semipermeable membrane, depending on the pore size certain elements are removed whilst others pass through.

The correct filtration process is selected specifically for your individual water issue.

What Is Microfiltration (MF)?

Microfiltration is the process of physically removing suspended solids from water, through a membrane. Microfiltration is often used in conjunction with other separation processes such as ultrafiltration and reverse osmosis.

The filters used in microfiltration have a pore size of approximately 0.1 microns (small). Bacteria and suspended solids are the only elements that can be removed through microfiltration.

A typical use for an ultrafiltration system can be:

A pre-treatment for another water treatment process

Certain types of effluent treatment

Certain oil and water separation applications

Treat wastewater

Sterilizing beverages and pharmaceuticals without sacrificing flavour

Processing dairy products while allowing protein through.

What Is Ultrafiltration (UF)?

Ultrafiltration blocks everything microfiltration can with the addition of viruses, requiring a slightly higher pressure to achieve this.

Although it requires higher pressure than MF, ultrafiltration can be powered by the pressure you get from the tap, making it popular in the commercial sector for drinking water.

It works the same way as MF by which a contaminated liquid passes through a membrane that is too large to fit through the membranes pore sizes, yielding a purified liquid stream.

Ultrafiltration filters have a pore size of approximately 0.01 micron (smaller).

UF can be used in the following processes:

Treating wastewater

Concentrating proteins

Chemical process separation

Separating oil/water emulsions

Removing pathogens from milk

Clarifying fruit juices

What Is Nanofiltration (NF)?

Nanofiltration membranes typically remove 50% – 90% of monovalent ions such as chlorides or sodium.

The design and operation of the filters used in NF are very similar to that of reverse osmosis, with some differences. Those being the membrane isn’t as ‘tight’ as RO membranes and a lower feedwater pressure is required.

Nanofiltration filters have a pore size of approximately 0.001 micron (smallest).

It has attained the name of the ‘softening membrane’ as it is often used to filter water with low amounts of total dissolved solids, to remove organic matter and to soften water.

NF can be used in the following processes:

Water treatment

Pre-treatment for RO

Pharmaceuticals

Textiles

Bakeries

Dairy

What’s The Difference Between Micro, Nano And Ultra-Filtration?

Ultimately they all do the same job but remove different elements depending on the water issue and the industry using it.

The pore size of the semipermeable membranes used is the only major difference between microfiltration, nanofiltration and ultrafiltration.

The different pore sizes allow for different elements allowed to be passed through, giving ultimate precision to treating your wastewater issue correctly and safely for the environment.

To remove all impurities all together, reverse osmosis is used. With tighter regulations and the many benefits it has, RO is becoming increasingly popular in the industrial sector.

Dependent on your water issue, microfiltration, ultrafiltration and nanofiltration may be used to purify and help you manage and treat your wastewater.

Each water issue is treated separately and a bespoke system is designed and built to reach the quality of water you want to achieve for your process.

A combination of more than one system is common to achieve such a precise quality of the water where regulations are tighter.

The first step to achieving your water solution is to understand the issues within your water. Membracon offers a free water analysis test to help you with this process, combined with expert knowledge to help and advise you through your project.

Larger organisations have a social responsibility to ensure waste products and chemicals are disposed of correctly. As large quantities of water and products are used in manufacturing processes, the impact they have on the environment is huge.

Due to the seriousness of incorrect wastewater disposal, companies saw fines of an average of £440,000 in 2017 with the added risk of imprisonment. Water companies are creating awareness around this issue, providing an environmentally friendly solution.

How Do Companies Benefit From Correctly Managing Wastewater?

There are many benefits of disposing of wastewater using modern membrane technology that is also good for the environment. Older methods such as using chemicals are slowly dying out due to the many hazards and health and safety risks they impose.

Benefits of using membrane technology include:

Operating costs are low

Reduces disposal costs if the water is reused/treated on-site

No hazardous chemicals to handle

Low maintenance – only a daily check-up required

Self-cleaning self-contained units

With the environment being a topic that’s not going away, people will start to look to the bigger culprits as they can have a bigger impact on making improvements.

The automotive industry as an example requires half a million litres of water to produce one small car. As so many car parts are made in different locations with different machinery requiring water to function and let's not forget the finishing process required to paint the car, it’s easy to see how this amount is so big.

This is why it’s so important that the water can be treated and reused where possible as when 70 million cars are produced globally, small improvements in the process can have a revolutionary impact.

How Can Companies Correctly Manage And Treat Wastewater

Modern membrane technologies allow for the treatment and management of wastewater to be an all in one system.

Dependent on your specific water issue, sometimes a number of units are combined to provide you with your unique water treatment solution.

Industrial wastewater is treated through the use of membranes. As water passes through, impurities are captured. This leaves you with clean water to re-use in production or to re-enter the water cycle safely.

There is a number of water filtration solutions, all dependent on the water quality you already have and the quality of water you want to achieve, a water expert would advise the best option.

Below is a list of water filtration systems available:

Reverse osmosis

Water recycling units

Ceramic filtration

Ultrafiltration

Nanofiltration

Coarse filtration

UV light

Each one allows a different level of water through, capturing certain impurities dependent on the membrane size. Reverse Osmosis for example only allows water to pass through.

Conclusion

Membrane technologies are the latest innovative solution to treating and managing industrial wastewater correctly with minimal hazards, upkeep and power.

With water being a key ingredient to the majority of manufacturing processes its benefits to treat it and reuse it where possible. Not only is this benefiting the environment but it’s a cost-effective way of managing wastewater.

The first step is to analyse your raw water, Membracon offers a free water analysis test to help you identify your water issue.

They design and build every unit fully bespoke to each customer's requirements. Get in touch today and one of our water filtration experts will be more than happy to assist.

Due to the seriousness of incorrect wastewater disposal, companies saw fines of an average of £440,000 in 2017 with the added risk of imprisonment. Water companies are creating awareness around this issue, providing an environmentally friendly solution.

How Do Companies Benefit From Correctly Managing Wastewater?

There are many benefits of disposing of wastewater using modern membrane technology that is also good for the environment. Older methods such as using chemicals are slowly dying out due to the many hazards and health and safety risks they impose.

Benefits of using membrane technology include:

Operating costs are low

Reduces disposal costs if the water is reused/treated on-site

No hazardous chemicals to handle

Low maintenance – only a daily check-up required

Self-cleaning self-contained units

With the environment being a topic that’s not going away, people will start to look to the bigger culprits as they can have a bigger impact on making improvements.

The automotive industry as an example requires half a million litres of water to produce one small car. As so many car parts are made in different locations with different machinery requiring water to function and let's not forget the finishing process required to paint the car, it’s easy to see how this amount is so big.

This is why it’s so important that the water can be treated and reused where possible as when 70 million cars are produced globally, small improvements in the process can have a revolutionary impact.

How Can Companies Correctly Manage And Treat Wastewater

Modern membrane technologies allow for the treatment and management of wastewater to be an all in one system.

Dependent on your specific water issue, sometimes a number of units are combined to provide you with your unique water treatment solution.

Industrial wastewater is treated through the use of membranes. As water passes through, impurities are captured. This leaves you with clean water to re-use in production or to re-enter the water cycle safely.

There is a number of water filtration solutions, all dependent on the water quality you already have and the quality of water you want to achieve, a water expert would advise the best option.

Below is a list of water filtration systems available:

Reverse osmosis

Water recycling units

Ceramic filtration

Ultrafiltration

Nanofiltration

Coarse filtration

UV light

Each one allows a different level of water through, capturing certain impurities dependent on the membrane size. Reverse Osmosis for example only allows water to pass through.

Conclusion

Membrane technologies are the latest innovative solution to treating and managing industrial wastewater correctly with minimal hazards, upkeep and power.

With water being a key ingredient to the majority of manufacturing processes its benefits to treat it and reuse it where possible. Not only is this benefiting the environment but it’s a cost-effective way of managing wastewater.

The first step is to analyse your raw water, Membracon offers a free water analysis test to help you identify your water issue.

They design and build every unit fully bespoke to each customer's requirements. Get in touch today and one of our water filtration experts will be more than happy to assist.

Dependent on your raw water, many different industrial water filtration systems can be used to remove impurities, solids and chemicals. Reverse osmosis is becoming an increasingly popular choice due to the fact it can remove more than most other systems.

Sometimes a combination of systems are used, this depends on the quality of the water you have, and the quality you need to achieve for your specific requirements.

Companies are becoming more aware of the impact their wastewater can have on the environment if not disposed of correctly. Just last week we saw Southern Water fined £126m and is under criminal investigation for the incorrect management of wastewater.

Below is everything you need to know about Reverse Osmosis including how it works, what sectors it can be used in and the benefits of implementing it.

What is Reverse Osmosis?

It’s a process in which raw water passes through a system that removes impurities and is often referred to as RO.

The system has cutting edge designed membranes that remove the impurities without the use of chemicals, resins or ion exchange beds.

Raw water or towns water is water that has not been treated or had any elements/minerals removed. Water comes into the RO system via a break tank or a fed from the mains. Depending on your geographical location the quality of your incoming water will differ.

Unlike other filtration systems that operate on a low-pressure water system, RO requires a higher pressure pump to drive the water through the membranes. This is due to it being able to remove more impurities than other filtration options.

The RO process improves the purity and quality of the incoming water supply by reducing the micro-Siemens and total dissolved solids (TDS).

Below is a diagram to show the capabilities of RO in comparison to Microfiltration, Ultrafiltration and Nanofiltration.

How Does Reverse Osmosis Work?

To understand how reverse osmosis works, lets first explain how osmosis works.

Let’s start with 2 cups, one has plain water in, the other has water and contaminants dissolved into it. A U-tube is then used, which is a beaker-shaped in a U-shape.

Right in the middle of the tube, imagine a bit of Gore-Tex that cuts the U in half. Gore-Tex is our “semipermeable membrane.” Gore-Tex is thin plastic, dotted with a billion tiny little holes that allow water vapour to pass through, but liquid to stay out.

In one arm of the U-tube the plain water is poured, in the other is the contaminated water. This is when the osmosis process begins. The level of liquid in the contaminated water arm will slowly rise, as the plain water moves through the Gore-Tex, to make both sides of the arm more equal in a contamination-to-water ratio.

This is due to the water finding an equilibrium. Because the one side of the arm is crowded with contaminants, pure water from the other side decides to move on over to make the concentration more equal or until the osmotic pressure (the pressure that happens as the molecules move is reached.

In osmosis, a lower-concentrate solution will filter its solvent to a higher concentrate solution. In reverse osmosis, we are just reversing the process, by making our solvent filter out of our high concentrate into the lower concentrated solution. So instead of creating a more equal balance of solvent and solute in both solutions, it’s separating out solute from solvent (the contaminants from water). These are more commonly referred to as concentrate and permeate.

This isn’t something that solutions really want to do, so the pressure is added to the equation to make reverse osmosis occur. Pressure forces the water to pass through the membrane, removing the impurities in the water.

What Sectors Can RO Be Used In?

Water is required in most manufacturing applications, it can be used to clean other machinery, process parts, produce consumables, wash out packaging before products are inserted and more.

RO can be used in the following sectors:

Automotive

Food & Beverage

Aerospace

Pharmaceutical

Agriculture

Finishing

Industrial

Automotive Industry

Water is a key element of the entire process of producing, maintaining and cleaning a vehicle and the components that comprise them. In the production stages of creating a vehicle, water usage is at its highest.

The wastewater from producing a car can contain metals, oils, grease and harmful chemicals from paint residue. If not treated properly these products can cause long-term damage to the environment and can be dangerous if they enter the main water system.

Reverse Osmosis can be used to produce the water needed in the initial part of the process and also at the end of the process where the wastewater can be processed again using RO. Once the water is cleaned and the waste products removed and disposed of correctly rather than just flushed away, it can then be reused in the production process, reducing waste and usage of wat

Sometimes a combination of systems are used, this depends on the quality of the water you have, and the quality you need to achieve for your specific requirements.

Companies are becoming more aware of the impact their wastewater can have on the environment if not disposed of correctly. Just last week we saw Southern Water fined £126m and is under criminal investigation for the incorrect management of wastewater.

Below is everything you need to know about Reverse Osmosis including how it works, what sectors it can be used in and the benefits of implementing it.

What is Reverse Osmosis?

It’s a process in which raw water passes through a system that removes impurities and is often referred to as RO.

The system has cutting edge designed membranes that remove the impurities without the use of chemicals, resins or ion exchange beds.

Raw water or towns water is water that has not been treated or had any elements/minerals removed. Water comes into the RO system via a break tank or a fed from the mains. Depending on your geographical location the quality of your incoming water will differ.

Unlike other filtration systems that operate on a low-pressure water system, RO requires a higher pressure pump to drive the water through the membranes. This is due to it being able to remove more impurities than other filtration options.

The RO process improves the purity and quality of the incoming water supply by reducing the micro-Siemens and total dissolved solids (TDS).

Below is a diagram to show the capabilities of RO in comparison to Microfiltration, Ultrafiltration and Nanofiltration.

How Does Reverse Osmosis Work?

To understand how reverse osmosis works, lets first explain how osmosis works.

Let’s start with 2 cups, one has plain water in, the other has water and contaminants dissolved into it. A U-tube is then used, which is a beaker-shaped in a U-shape.

Right in the middle of the tube, imagine a bit of Gore-Tex that cuts the U in half. Gore-Tex is our “semipermeable membrane.” Gore-Tex is thin plastic, dotted with a billion tiny little holes that allow water vapour to pass through, but liquid to stay out.

In one arm of the U-tube the plain water is poured, in the other is the contaminated water. This is when the osmosis process begins. The level of liquid in the contaminated water arm will slowly rise, as the plain water moves through the Gore-Tex, to make both sides of the arm more equal in a contamination-to-water ratio.

This is due to the water finding an equilibrium. Because the one side of the arm is crowded with contaminants, pure water from the other side decides to move on over to make the concentration more equal or until the osmotic pressure (the pressure that happens as the molecules move is reached.

In osmosis, a lower-concentrate solution will filter its solvent to a higher concentrate solution. In reverse osmosis, we are just reversing the process, by making our solvent filter out of our high concentrate into the lower concentrated solution. So instead of creating a more equal balance of solvent and solute in both solutions, it’s separating out solute from solvent (the contaminants from water). These are more commonly referred to as concentrate and permeate.

This isn’t something that solutions really want to do, so the pressure is added to the equation to make reverse osmosis occur. Pressure forces the water to pass through the membrane, removing the impurities in the water.

What Sectors Can RO Be Used In?

Water is required in most manufacturing applications, it can be used to clean other machinery, process parts, produce consumables, wash out packaging before products are inserted and more.

RO can be used in the following sectors:

Automotive

Food & Beverage

Aerospace

Pharmaceutical

Agriculture

Finishing

Industrial

Automotive Industry

Water is a key element of the entire process of producing, maintaining and cleaning a vehicle and the components that comprise them. In the production stages of creating a vehicle, water usage is at its highest.

The wastewater from producing a car can contain metals, oils, grease and harmful chemicals from paint residue. If not treated properly these products can cause long-term damage to the environment and can be dangerous if they enter the main water system.

Reverse Osmosis can be used to produce the water needed in the initial part of the process and also at the end of the process where the wastewater can be processed again using RO. Once the water is cleaned and the waste products removed and disposed of correctly rather than just flushed away, it can then be reused in the production process, reducing waste and usage of wat

Reverse Osmosis (RO) is growing in popularity when it comes to managing and treating wastewater, especially in industrial processes.

Companies are becoming aware of just how important the responsibility they have when dealing with such large quantities of water. Water filtration systems like RO are an investment that companies should be making.

They provide a safer working environment, less maintenance and over time will save money. They’re also required to meet certain regulations and laws.

What Is Wastewater?

Wastewater is any water that has been affected by human use, this can be from domestic, industrial, commercial or agricultural activities. It can be transported to sewers or wastewater treatment plants.

When wastewater is discharged into the environment without suitable treatment this then causes water pollution. Last month saw Southern Water penalised with a £126m payout due to spillage of wastewater into the environment.

As society is becoming more eco-conscious, regulations and rules are becoming stricter.

Penalties are also becoming heavier, the managing director of the business that fails to meet regulations could face imprisonment.

Having the correct wastewater treatment and management is crucial to your business. Not only to meet regulations but it can also save money by reusing water that would otherwise get disposed of.

Below is a list of some of the industries that generate wastewater through production:

Automotive

Food And Beverage

Agriculture

Finishing

Aerospace

Industrial

Pharmaceutical

How Can Reverse Osmosis Be Used To Treat Wastewater

Although there’s a variety of water filtration solutions to manage and treat wastewater, RO is becoming increasingly popular. RO is capable of rejecting 99.9% of bacteria.

Reverse Osmosis systems can be used combined with other water filtration units. Dependent on each water solution is the quality of water you have to treat and the desired quality of water for reuse.

This will differ for each solution as raw water quality varies with location. It also depends on the contaminants that have been used in production.

RO works by removing impurities from contaminated water. It does this through the process of pressure, forcing the contaminated solution through membranes. After the water is treated it can be reused in production or can be disposed of safely.

Is RO A Green Solution For Industrial Waste Water Treatment?

Traditional water treatment methods require chemicals, which poses more than one risk. Holding chemicals on-site, transporting them and having someone manage them are all health and safety risks.

It’s also better for the environment if the treatment takes place on-site as opposed to frequent collections of wastewater by truck.

Modern membrane technologies used in RO don’t require any chemicals, it uses electricity and high-pressure water.

RO systems also require very little maintenance, they are self-cleaning, self-contained units.

The wastewater they treat can be disposed of safely or reused and recycled back into production. This is a huge benefit as it saves storage space and saves money.

Conclusion

RO is just one of the options when it comes to managing and treating wastewater. However, due to the many benefits, it’s becoming an increasingly popular choice in manufacturing processes.

Every single company will face different challenges with its wastewater as there are so many varying factors that affect the quality.

To understand your specific water issue Membracon offers a free water analysis test. This way you can establish the purity of the water you already have, and we can then offer the best solution for you to achieve your required water quality target.

Companies are becoming aware of just how important the responsibility they have when dealing with such large quantities of water. Water filtration systems like RO are an investment that companies should be making.

They provide a safer working environment, less maintenance and over time will save money. They’re also required to meet certain regulations and laws.

What Is Wastewater?

Wastewater is any water that has been affected by human use, this can be from domestic, industrial, commercial or agricultural activities. It can be transported to sewers or wastewater treatment plants.

When wastewater is discharged into the environment without suitable treatment this then causes water pollution. Last month saw Southern Water penalised with a £126m payout due to spillage of wastewater into the environment.

As society is becoming more eco-conscious, regulations and rules are becoming stricter.

Penalties are also becoming heavier, the managing director of the business that fails to meet regulations could face imprisonment.

Having the correct wastewater treatment and management is crucial to your business. Not only to meet regulations but it can also save money by reusing water that would otherwise get disposed of.

Below is a list of some of the industries that generate wastewater through production:

Automotive

Food And Beverage

Agriculture

Finishing

Aerospace

Industrial

Pharmaceutical

How Can Reverse Osmosis Be Used To Treat Wastewater

Although there’s a variety of water filtration solutions to manage and treat wastewater, RO is becoming increasingly popular. RO is capable of rejecting 99.9% of bacteria.

Reverse Osmosis systems can be used combined with other water filtration units. Dependent on each water solution is the quality of water you have to treat and the desired quality of water for reuse.

This will differ for each solution as raw water quality varies with location. It also depends on the contaminants that have been used in production.

RO works by removing impurities from contaminated water. It does this through the process of pressure, forcing the contaminated solution through membranes. After the water is treated it can be reused in production or can be disposed of safely.

Is RO A Green Solution For Industrial Waste Water Treatment?

Traditional water treatment methods require chemicals, which poses more than one risk. Holding chemicals on-site, transporting them and having someone manage them are all health and safety risks.

It’s also better for the environment if the treatment takes place on-site as opposed to frequent collections of wastewater by truck.

Modern membrane technologies used in RO don’t require any chemicals, it uses electricity and high-pressure water.

RO systems also require very little maintenance, they are self-cleaning, self-contained units.

The wastewater they treat can be disposed of safely or reused and recycled back into production. This is a huge benefit as it saves storage space and saves money.

Conclusion

RO is just one of the options when it comes to managing and treating wastewater. However, due to the many benefits, it’s becoming an increasingly popular choice in manufacturing processes.

Every single company will face different challenges with its wastewater as there are so many varying factors that affect the quality.

To understand your specific water issue Membracon offers a free water analysis test. This way you can establish the purity of the water you already have, and we can then offer the best solution for you to achieve your required water quality target.

Although all water filtration systems are achieving the same thing, the process can differ depending on your chosen solution. Reverse osmosis is a solution that can reject up to 99.9% of bacteria.

This is why it's popular in industrial processes where there’s a variety of contaminants such as grease, oil, paint and chemicals.

Read on to find out what RO is, how it works and what industries use it.

What Is Reverse Osmosis?

Often referred to as RO, reverse osmosis is a type of water filtration solution that removes impurities. Some towns have poor water quality due to an in balance, for example, some water has too much fluoride in it.

This means the water needs treating before it can be used. Solids can also be found in water which needs capturing and removed.

Water filtration systems such as RO can be used to provide companies or towns with the correct water. They can also be used to manage and treat wastewater.

An example of this would be an automotive company that manufacture car parts, the water they’ve used to clean machinery cannot be disposed of down the drain. This would harm the environment and defy regulations and laws.

RO would be able to remove the contaminants such as paint, grease and oil so that it could be reused in production or disposed of correctly.

RO is becoming increasingly popular due to the capabilities it has in comparison to other water filtration solutions. It’s not uncommon for a combination of systems to be used to ensure your required water quality is achieved.

How Does RO Work?

Water passes through a membrane that removes impurities without the use of chemicals, resins or ion exchange beds. The pressure is applied to force the solution through the semipermeable membrane as illustrated below.

There are a variety of membranes that come in different shapes and sizes depending on the impurity they need to capture and the quantity of water passing through.

Who Uses Water Filtration Systems?

In many, if not all industries there are requirements, this could be for the products themselves (like medication or food) or the equipment and surroundings used.

Agriculture is an example of this, the area in which the cows are milked needs to be kept clean so there’s no cross-contamination between different herds.

If the area was to be cleaned with the incorrect quality of water this could have huge implications on the health of livestock, resulting in damaging the brand reputation and sales.

Another reason water filtration systems are required can be due to location issues. Depending on where you are, water can vary hugely. Your raw water may not be suitable or clean enough to use in the production or for cleaning.

By installing a system like RO you can clean the water you already have access to rather than purchasing filtered water. More than one system can be used to achieve a specific level of water quality.

Below is a list of sectors that RO can be used in:

Automotive

Food & Beverage

Aerospace

Pharmaceutical

Agriculture

Finishing

Industrial

Benefits From Installing an RO System

Traditional filtration systems use chemicals to treat water, which causes a lot of hazards not just in the workplace but for staff too.

Installing an RO system saves money in the long run as you’re treating your own wastewater instead of paying somebody else to collect and treat it. You can then dispose of it yourself or reuse it in production.

Another benefit of implementing RO is it’s a self-contained unit that cleans itself. It only requires a daily check from onsite personnel rather than being actively maintained.

The membranes can last 2-3 years depending on the quality and quantity of feed water. All membranes can be replaced in any given system within hours, compared to a resin-based system which could take days.

Conclusion

RO removes impurities with cutting edge designed membranes, without the use of chemicals. It's becoming an increasingly popular solution to companies and towns water issues.

To understand your specific water issue and to ensure you’re water filtration choice is right for you, Membracon offers a free water analysis test. Membracon design and build every unit fully bespoke to suit each customers requirements.

This is why it's popular in industrial processes where there’s a variety of contaminants such as grease, oil, paint and chemicals.

Read on to find out what RO is, how it works and what industries use it.

What Is Reverse Osmosis?

Often referred to as RO, reverse osmosis is a type of water filtration solution that removes impurities. Some towns have poor water quality due to an in balance, for example, some water has too much fluoride in it.

This means the water needs treating before it can be used. Solids can also be found in water which needs capturing and removed.

Water filtration systems such as RO can be used to provide companies or towns with the correct water. They can also be used to manage and treat wastewater.